Thermocoax delivers a comprehensive package for precise, controllable deposition and growth of micro and nano structures that will improve the whole system stability :

![]()

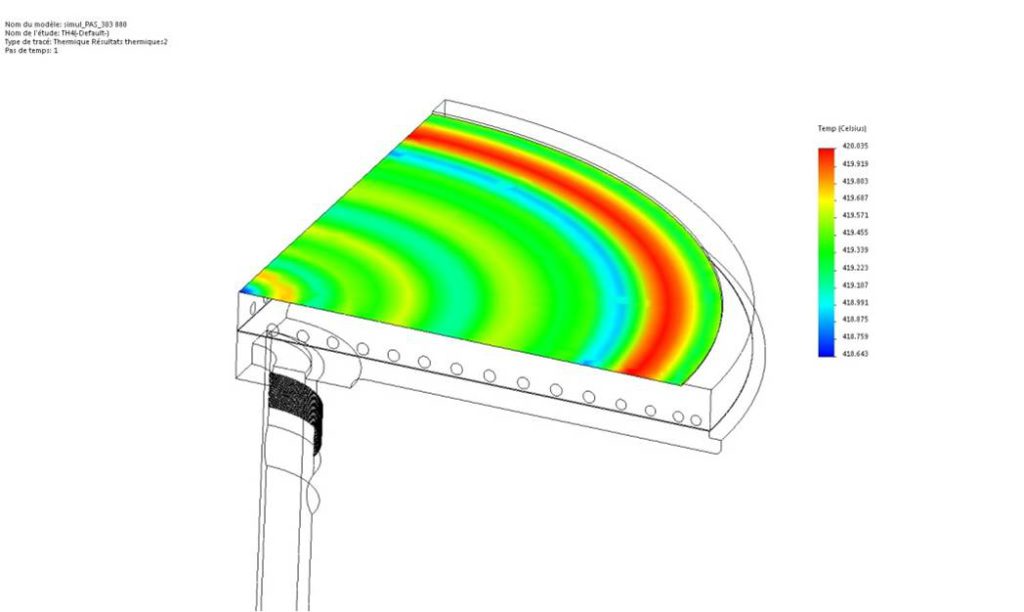

- 3D thermal modeling using ACE+ or equivalent to define the best solution matching your chamber environment

- Engineering and in-house prototyping

- Custom prototype

- Serial production

Plate <1 000°C

Metallic Substrate Heater (Inconel, special alloys)

- Engineering 3D Thermal modeling

- Prototyping and Semiconductor standard cleaning

- Bulk Production

THERMOCOAX Inconel Chucks

Application : Deposition Process requiring High Temperature Uniformity (ALD Atomic Layer Deposition, CVD)

From 3D thermal modeling to bulk production, THERMOCOAX has the capability to design heated chucks matching the most stringent specifications

- Up to 1000°C with temperature uniformity specified

- Material: Inconel, other material

- Voltage 24-220 VAC or DC

- UHV Vaccum < 10−7 Pa

- Size: 6" / 8" / 12" / 14" or custom

Single or Multizone heater (to 7 zones ). Made with THX original True Cold End Heater Technology

Heat / Cooling design options

THERMOCOAX custom high temperature ceramic/metal connectors (650°C). Compatible with high vacuum

Feedthrough : custom bushings or flanges

(*) The temperature uniformity under working conditions depends on the specifications and the chamber environment

Plate < 600°C

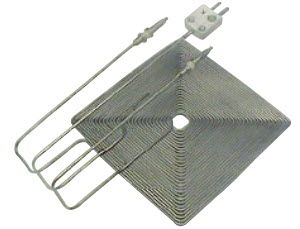

Stainless Steel Substrate Heater to 600°C

Stainless Steel Substrate Heater to 600°C

- Engineering 3D Thermal modeling. Custom design

- Prototyping and Semiconductor standard cleaning

- Bulk Production

THERMOCOAX Stainless Steel Chucks

Application : Deposition Process requiring High Temperature Uniformity (CVD Chemical Vapor Deposition)

From 3D thermal modeling to bulk production, THERMOCOAX has capabilities to engineer heated chucks matching the most stringent specifications

Up to 600°C with a temperature uniformity 2°C (*)

- Material: Stainless Steel

- Voltage 24-220 VAC or DC

- UHV Vaccum < 10−7 Pa

- Size: 6" / 8" / 12" / 14" or custom

- Single or Multizone heater (to 7 zones ). Made with THX original True Cold End Heater Technology

- Heat / Cooling design options

- THX custom high temperature ceramic/metal connectors. Compatible with high vacuum

- Feedthrough : custom bushings or flanges

(*) The working temperature under working conditions depends on the specifications and the chamber environment

Plate < 300°C

- Wafer Plate Heater to 300°C

- Engineering 3D Thermal modeling (ACE+ or other)

- Cast and machined Aluminum - Custom Mold

- 2 Heating zones + Cooling option

THERMOCOAX Aluminium Plates

Applications : PVD

Cast chucks allow higher temperature uniformity with aluminium material, without the risk of outgassing, and the heaters are enclosed inside the aluminium

- Working temperature 300°C. Tests performed up to 350°C

- Cooling option : For either cast or machined technology, cooling tubes can be enclosed to accelerate cooling time

- Size: to 450mm

- Several heater types : Cold end or True cold ends heaters, Dual core

- Thermal surface treatment for hardening

- Single or several zones heating design

- Surface flatness assured at working temperature with machined aluminium chuck option

- Thermocouple integrated for temperature regulation and safety

Coil heater

- Substrate UHV Coil Heater to 1000°C

- Low maintenance and heavy duty

- Cost effective solution for UHV chamber

- Easy installation

THERMOCOAX Coil Heater Plates

Applications : R&D deposition tools

- Maximum working temperature 1000°C

- Diameter up to 200mm ( Options for higher diameters or other shapes)

- Compactness : Cold end heater coil laser welded with thermocouple

- Coils are custom to match exactly your specifications and come in different shapes, sizes and power ratings

- Heater suitable for working at low voltage 24VDC

- Suitable for use in air, plasma, high pressure, high frequency or ultra-high vacuum environments

- Made with THERMOCOAX original Cold end technology heaters

Feedthrough - Gas Delivery

All applications are engineered with NDA. Pictures displayed are not representative or contractual

- Gas Delivery Aps

- The medium is transfered avoiding changes in viscosity, eliminating condensation and crystallisation

- Optimal temperature uniformity

- Custom small size OD 5mm MI cable heat feedthrough

THERMOCOAX Gas Delivery Aps

Applications: heated feedthrough for deposition tools (CVD-ALD) - Gas transfer - evaporators

- Production capacities in vacuum oven brazing

- Hardpacked MI cable insulation allows the cable to be given virtually any shape without deterioration under working conditions

- Thermocouple / RTD integrated

- Manufacturing process fully controlled: traceability, subcontractor assessment, internal and external audits, regulatory compliance)

- Fully custom design for both THERMOCOAX ISOPAD heated hoses, silicone heating jackets and THERMOCOAX gas heated transfer lines

- Heater suitable for work with a low voltage 24VDC

- Suitable for High Vacuum Environments

- Possibility to distribute the power along the tube according to the thermal profile

Cold End Heaters

- True cold end technology without outside connectors

- Mgo compaction for optimal dielectric withstand

- Custom sheath and ratings

THERMOCOAX mineral cable technology

Applications : heating applications up to 1000°C

Thermocoax heaters represent a comprehensive range of mi cable heaters, whatever the requested power, temperature, or media. The heaters can be fully customized to match exactly your requirements, including the option to have several sheaths